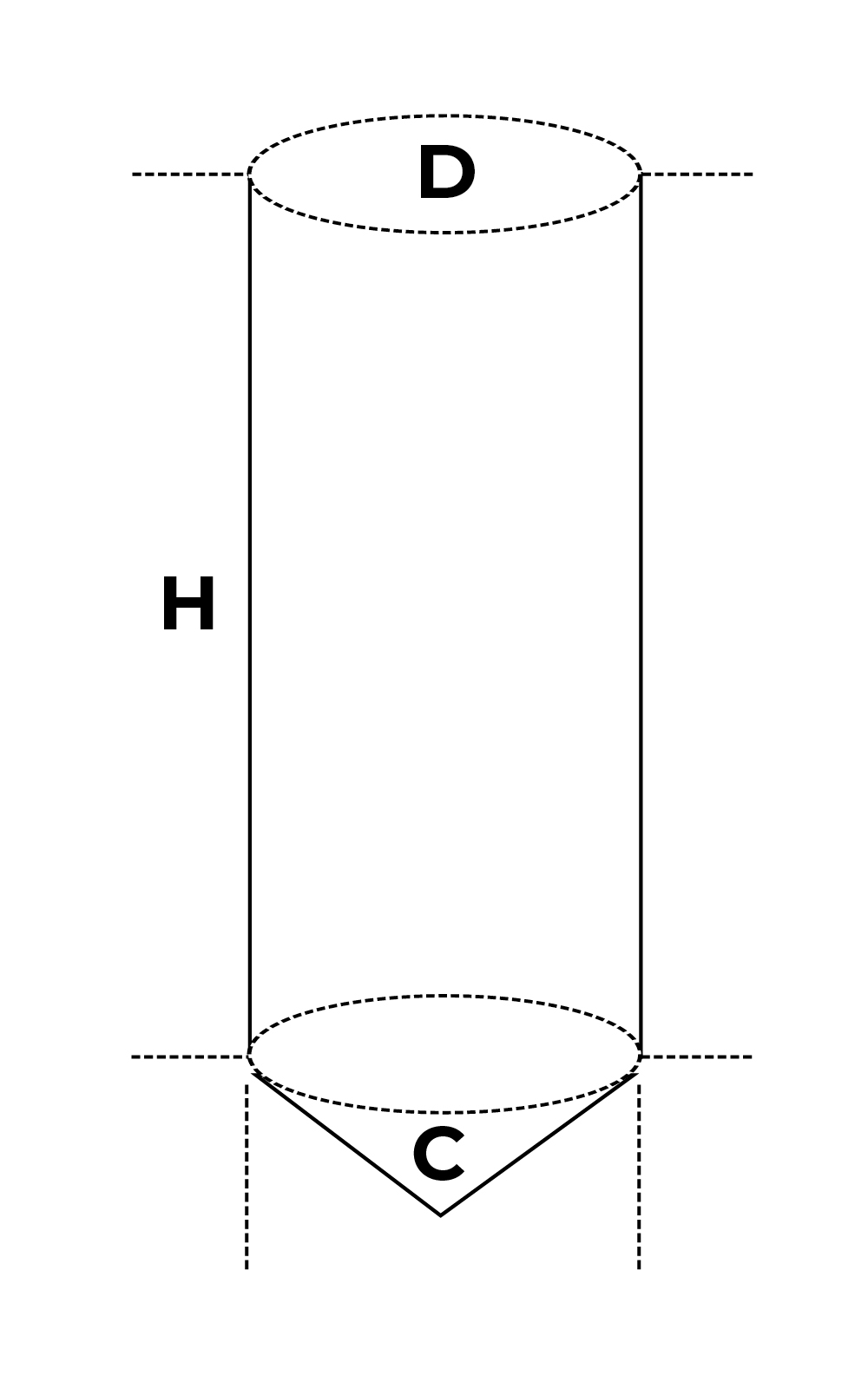

Our silos are composed by ferrules, each one is formed by three different flanged sheets which are then bolted with each other.

Each ferrule will bolted and joined to the next until the desired height.

Thanks to this method of mounting each silo can be easily disassembled and reassembled with a different height, a different arrangement of nozzles or holes for the passage of tubes.

The internal discharge cone can be 90 degrees or 60 degrees depending on the stored material. It too is formed from different flanged sheets, which helps during assembly and disassembly.

ROOF

The roof is constituted from several sectors whose number depend from the diameter of the silo. The sectors are mounted through the circumferential flange, once every sector is fixed, the roof is fixed to the ferrule.

FERRULE / CYLINDER

The cylinder is made up by panels h:2000 and / or h:1000; the number of the panels constituting the ferrule depend from the diameter of the silo. As per today , we are offering two silos diameters : 5.500 mm and 4.500 mm for powder as well as granules.

Bigger silos (percentage-wise) are more economic than smaller ones ! In fact, as you are aware of, there are some basic costs as silos foundations, accessories, etc. that do not depend from size of silos! Additionally, the impact on the transport, is very low. Additionally , bolted silos are more stiff and can better stand vibration and possible implosions. This is the reason why, as per consolidated experience and site conditions, companies are preferably going for larger silos ( up-to 500m3).

FERRULE / SKIRT / DOOR

The skirt of the silo is made up of h:2000 high panels. The number of modules constituting a ferrule/skirt depends on the diameter of the silo. On one of the panels of the skirt is to be built the access door of the silo, while at bottom of skirt will be welded the base plate which allows fixing the silo on the ground or on a weighing beam.

CONE

The cone may have different outlet angle (60 ° – 90 °), and its circumference is divided according to the panels of the ferrule / cone, while its height is divided into three sections (large-cone, medium-cone, small-cone). The three sections of the cones are sealed through an adhesive sealing mousse.