Universal DosyMix

Metalworks Universal DosyMix is four products (either powder and/or granules) volumetric batcher complete with a

continuous blender for the feeding of processing equipment and/or machines. For each product a buffer tank and an

electronically controlled auger feeder (that automatically adjust the RPM depending from the set throughput) have

been foreseen. Each of the four products’ feeder can be either fed mechanically and/or pneumatically by a pressure

conveying system or vacuum loader.

Experience proves that this device is broadly used for continuously dosing, mixing and feeding a blend of few products

to a machine (an extruder for instance). One of the most common and useful application is to add CaCO 3 to PVC dry-

blend along with reprocessed material and master batch and feed and extruder for the production of CaCO 3 highly filled

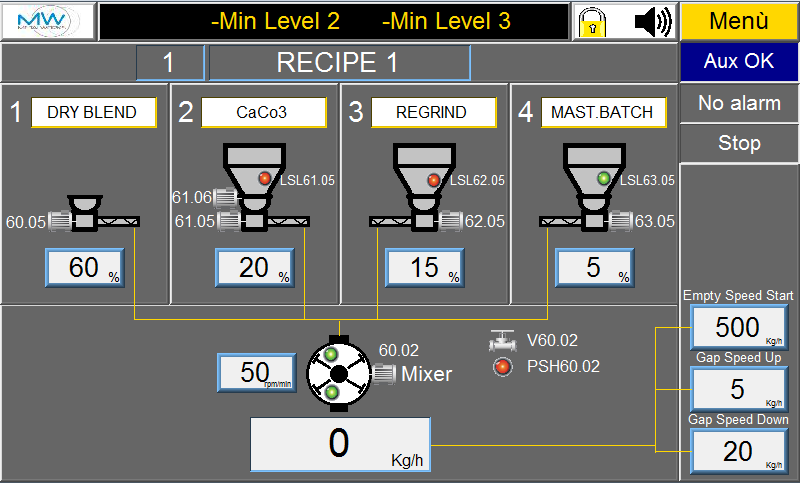

PVC pipes. We are dealing with a continuous process therefore the percentage (%) of the four products can be instantly

modified as needed / requested by the process and final product.

Dosing & Mixing

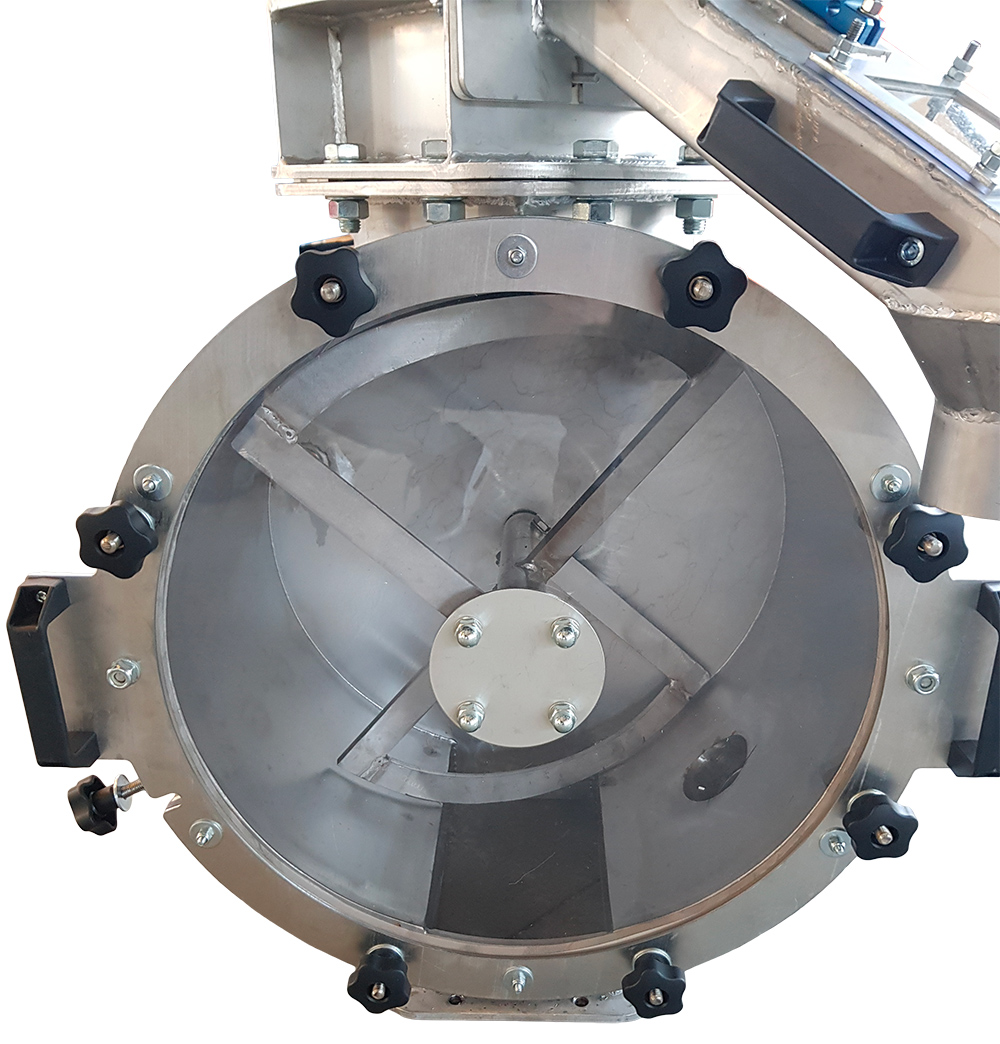

The four products (Dry-Blend, CaCO 3 , Regrind and Master Batch for instance ..) are continuously

blended by means of a continuous blender volumetrically fed by the volumetric auger feeders , driven by brushless

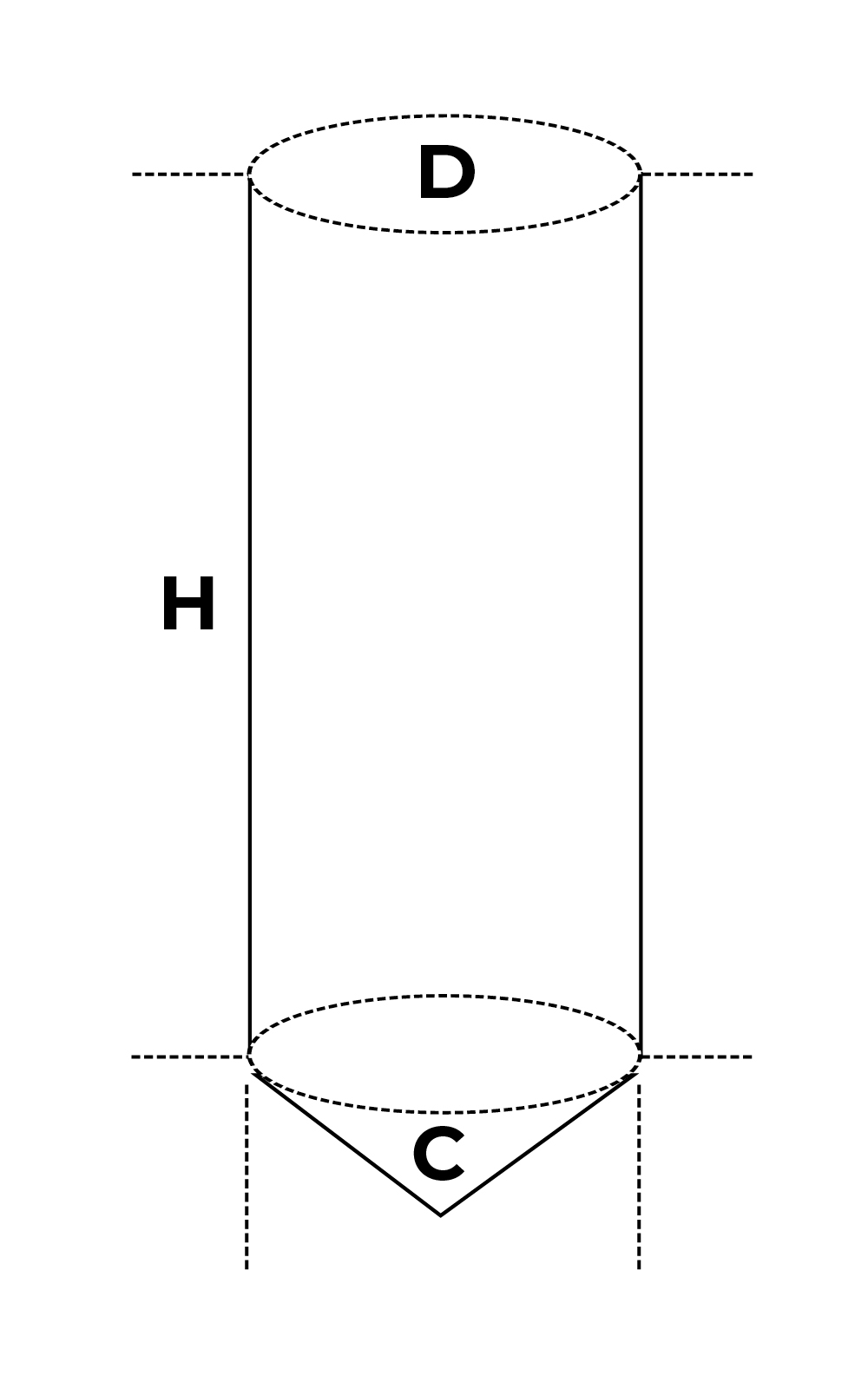

electric motor, each of the four products’ buffer tank is equipped with. The continuous blender will be fitted on the

feeding screw the extruder is equipped with. Volume of the mixer is calculated in order to grant, depending from the

throughput of the extruder, the most suitable permanence time of the products to be blended.

The brushless motors each volumetric feeder is equipped with as well as mixer and accessories are driven and

controlled by a dedicated / standalone PLC electric panel as well as a touch screen HMI human interface.

Remote trouble shooting as well as modifications/tuning of the Software is granted by Internet Router Ewon

card & protocol.