Metalworks bags slitting and emptying machine represents the latest most advanced technology for bags slitting and emptying complete with de-palletizer and empty bags compactor.

Metalworks machine is designed and manufactured for heavy duty operations. It is strong, efficient and reliable suitable for high performances (up-to 1.000 bags /h) and unbeatable emptying efficiency (up-to 99,9 %).

Metalworks machine mainly consists of:

– De-palletizing

– Bags slitting

– Bags Emptying

– Empty bags compacting

– Electric driving and controlling panel

Option :

– Automatic stuck-up of empty pallets

– Magazines for full pallet storage

De-palletizer

De-palletizing is made layer-by-layer by electro-pneumatically operated harpoons grappling the entire layers the pallets

consists of. Harpoons are not moving up-down. The pallet does. In this way higher efficiency, easier and safer

operations along with less demanding maintenance is granted.

Experienced proves that Metalworks design is granting a great number of advantages/technical features as:

1. The entire machine, especially the de-palletizer is a heavy duty one. Pallets are electro-mechanically handled by

high resistance double chain set-up highly reliable and maintenance free.

2. Limited up-down movements of the pallet and harpoons drastically reduce the dead times for better

functionality, higher performances and significantly less maintenance of the machine.

Additionally, vibrations are practically absent therefore none of the problems suffered by other type of machine

are experienced by Metalworks bags slitting and emptying machine.

3. Thanks to this special design, differences of thickness of the bags does not affect the performance of the

machine. Moreover, it is practically impossible that the bags, the layer consists of, will not consistently

harpooned, slit and emptied.

BAGS SLITTING

BAGS EMPTYING

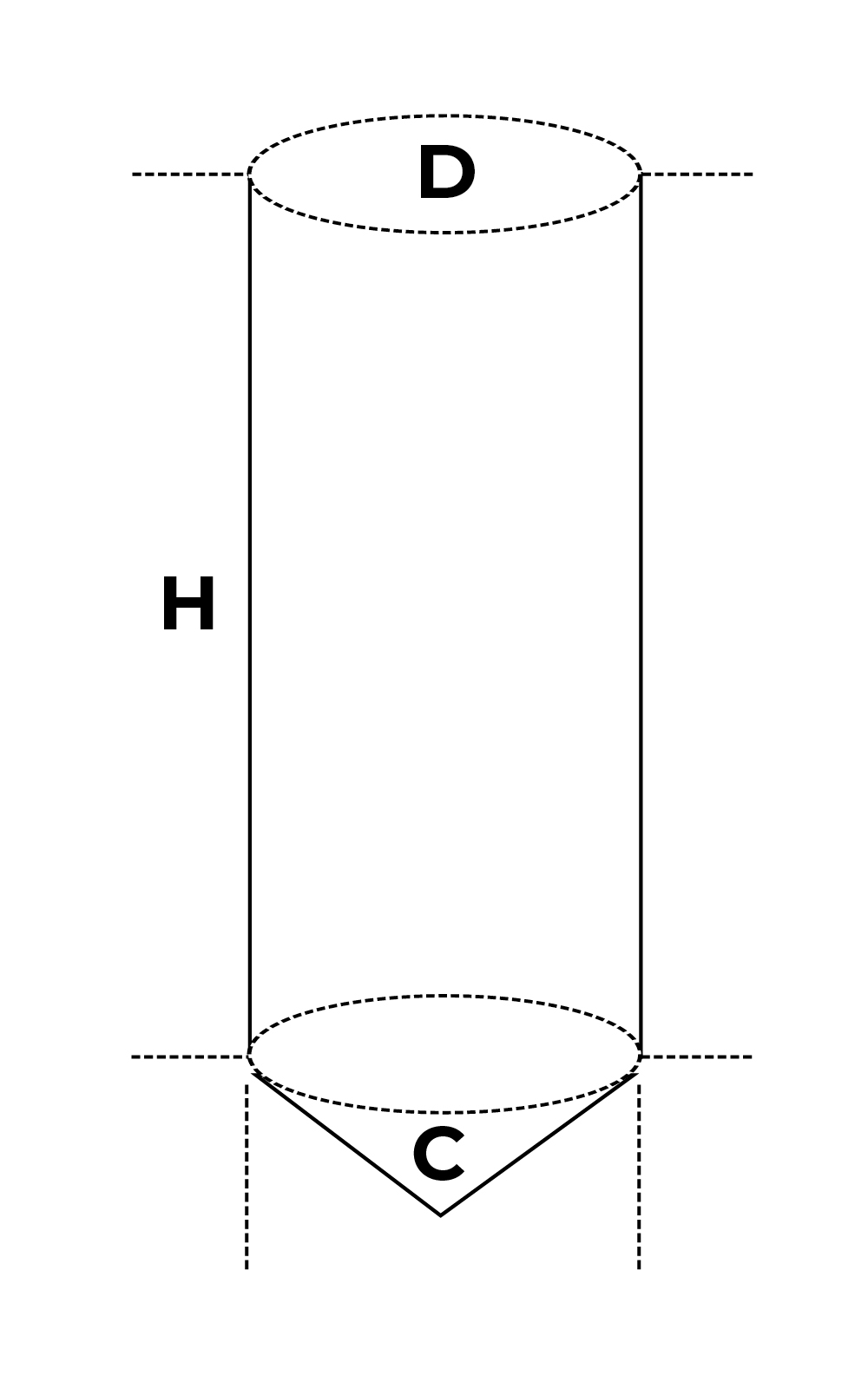

Metalworks grants the full Bags Emptying by intensive tumbling of slit bags moving into a rotating drum. The result is

an accurate emptying of bags, direct discharging of debagged product into the machine hopper, automatic gathering

and feeding of empty bags into the empty bags compactor. Simple, effective and reliable as a heavy-duty highly and

flexible machine needs to be.

Experience proves that other machines available on the market , mostly due to economic reasons, are slitting the bags

(each layer consists of) by “sliding” the entire layer of bags on rotating blades. The matter is, as it often happens, that

the bags are not evenly sitting thus, are not uniformly slit and might fall into the machine hopper, without even getting

slit too.

Poor slitting will make the subsequent mechanical “shaking” not suitable to the full emptying of the bags. In fact, some

granules will be retained that inevitably will get lost with the empty bags.

Shaking, among others, leads to additional vibrations whose negative consequences are increased and faster wearing

and frequent and costly maintenance.

Empty bags compacting

Once the bags are slit and emptied they automatically and continuously moving into an empty bag screw compactor.

filling a PE plastic tube for easy handling. Once the PE tube is full an alarm signa will be provided for its replacement.

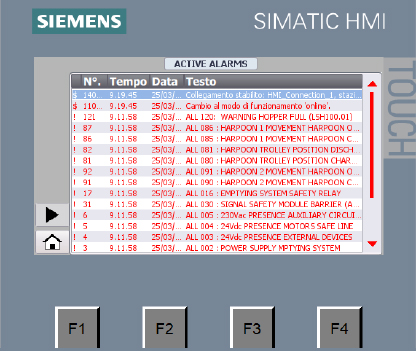

Electric Control, Production Management

& Remote trouble shooting

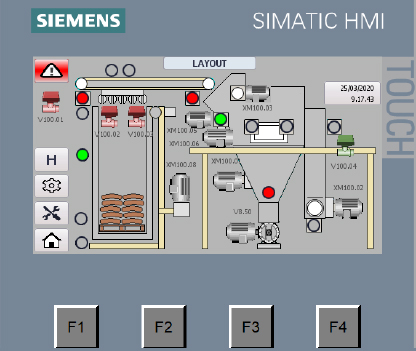

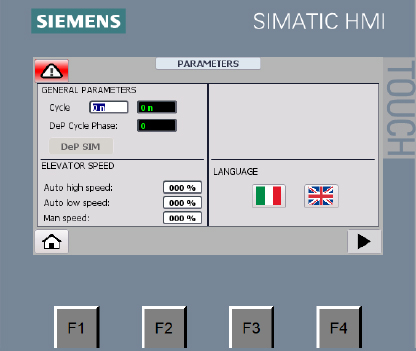

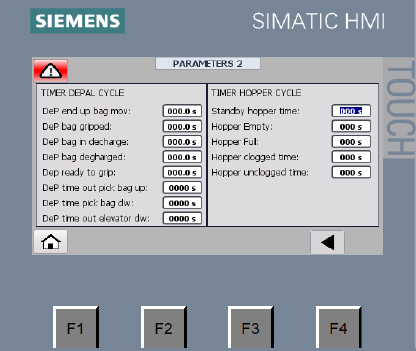

Metalworks machine is driven by a centralized electrical panel for driving and controlling (Manually and

Automatically) the entire machine from pallet incoming up-to empty bags compacting. Logic is PLC controlled.

Human interface is granted by an HMI touchscreen. Among others, alarms and notices/warning are handled.

In case the machine will be interfaced / interlocked with up and/or down-stream equipment (potential

free) contacts might be agreed among the parties involved.

Further Option:

Remote trouble shooting as well as modifications/tuning of the Software is granted by Internet Router Ewon

card & protocol.

Production management as totalization, within a set period of time, of the number of debagged bags as number of

debagged layers and relevant weight.

Interlocking and data exchange with a compatible local ERP system of the data the Metalworks’ SCADA is locally

memorizing by its own data base (SQL). Data con be exchanged between Customer’ ERP and Metalworks’ SCADA

by set Ethernet protocol .

Option

In order to increase the capacity of the machine and limit to the minimum the dead time for unloading the empty

pallet and load the upcoming full pallet, the machines can be equipped with the following option:

Automatic stuck-up of empty pallets:

It can automatically stuck-up up to 6 empty pallet that once reached can be collect ed and removed in one go by forklift.

Full pallets magazine:

A roller conveyor, in automatic mode, can store and move full pallets for the feeding of the automatic de-palletizer machine. Depending from logistic and available space 3 to 5 complete pallets are loaded on the full pallets magazine.